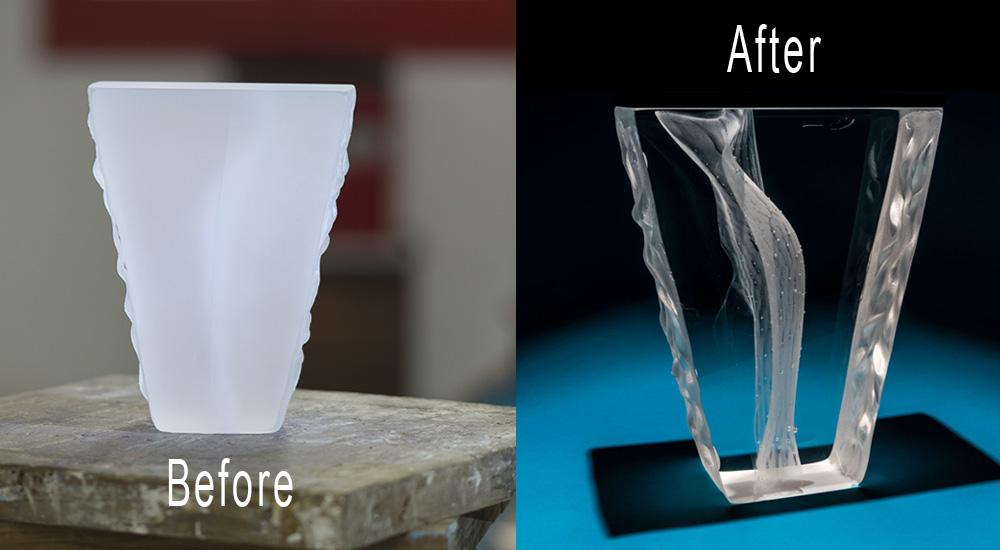

Post updated on August 10, 2024.Polishing glass, especially optical glass, is a crucial step in the glass sculpting process. After firing the glass sculpture in the kiln, the next challenge is to polish it to achieve optical transparency. The process requires patience...

Polishing glass to achieve optical transparency

read more